- HOME

- About

-

Product

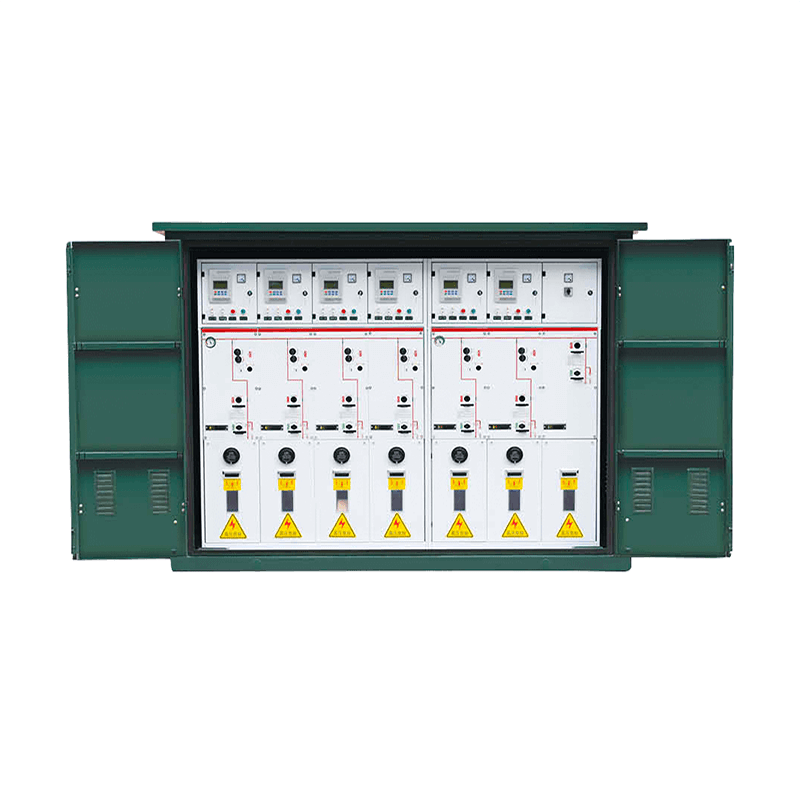

- Box type substation

-

High voltage switchgear

TBBZ high voltage reactive power automatic compensation device

HXGN15-12 box type fixed AC metal enclosed switchgear

KYN28A-12 armored removable enclosed switchgear

SHGT-12 Solid Fully Insulated Enclosed Ring Network Switchgear

GZD (W) (microcomputer control) DC power supply cabinet

XGN ☐ - 12 intelligent solid insulation cabinet

SHSRM16-12 Inflatable (totally enclosed) ring network cabinet

HXGN17-12 box type fixed AC metal enclosed switchgear

XGN2-12 box type fixed metal enclosed switchgear

XGN66-12 (Z) fixed enclosed switchgear

KYN28A-24 armored removable AC metal enclosed switchgear

KYN61-40.5 (Z) armored removable AC metal enclosed switchgear

- Box type opening and closing

-

Low-voltage switchgear

XL-21 low-voltage power distribution cabinet

MNS low-voltage draw out switchgear

GCS low-voltage draw out switchgear

GCKLV withdrawable switchgear

GGD low-voltage switchgear

GGJ Low voltage reactive power intelligent compensation device

JXM transparent anti-theft city network box

SHF1-Q-S low-voltage cable junction box (SMC)

SHF1-Q-S/L low-voltage cable junction box (SMC)

JP integrated distribution box (compensation/control/terminal/lighting)

-

Components series

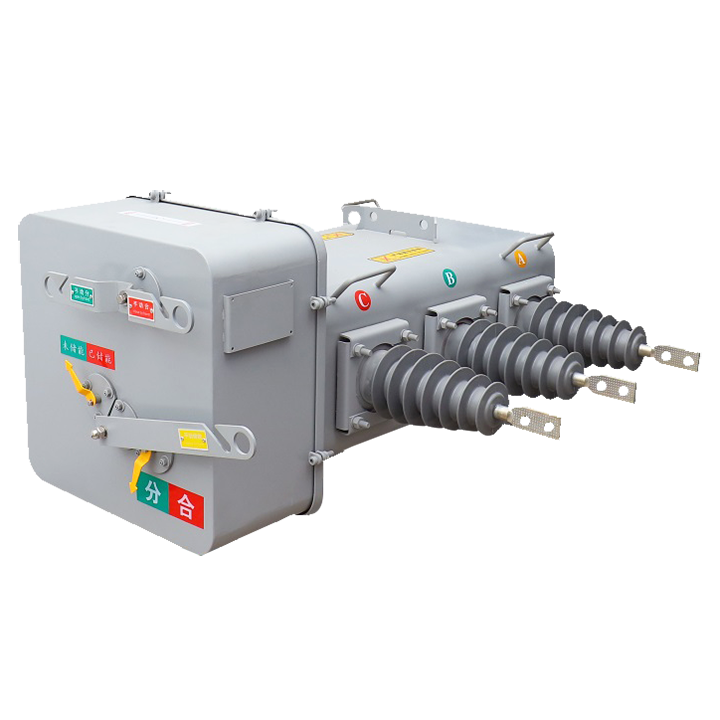

LW3-12 primary and secondary fusion SF6 circuit breaker

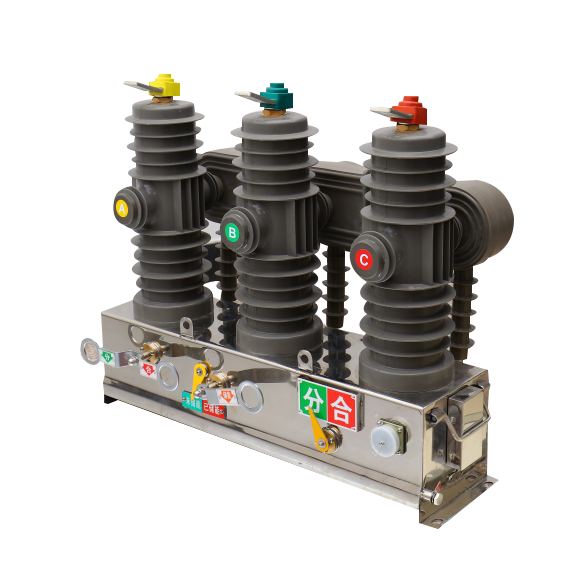

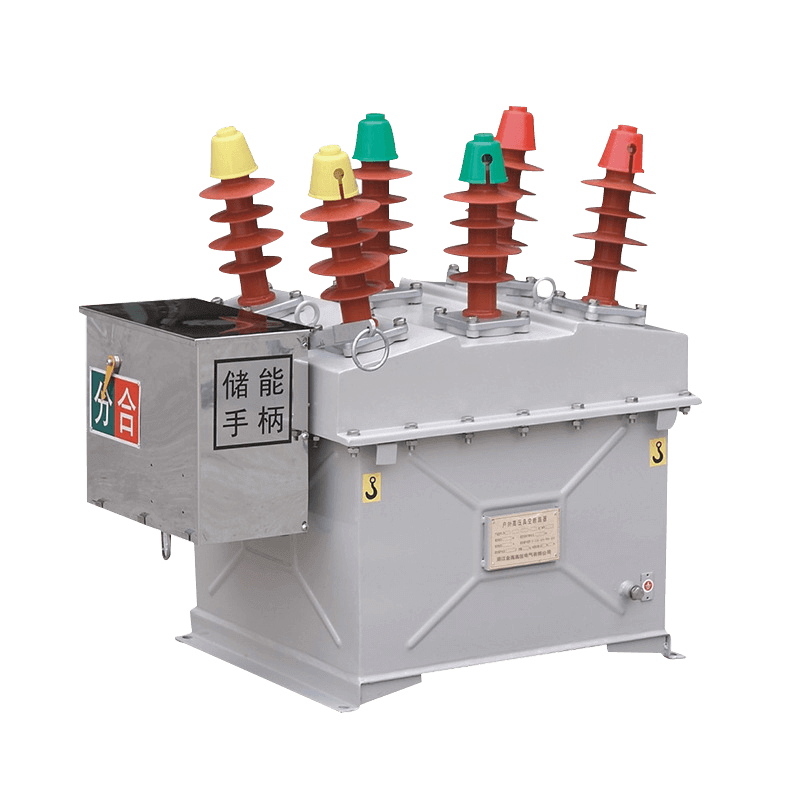

ZW43-12 (G) outdoor high-voltage vacuum circuit breaker

ZW32-40.5 outdoor high-voltage AC vacuum circuit breaker

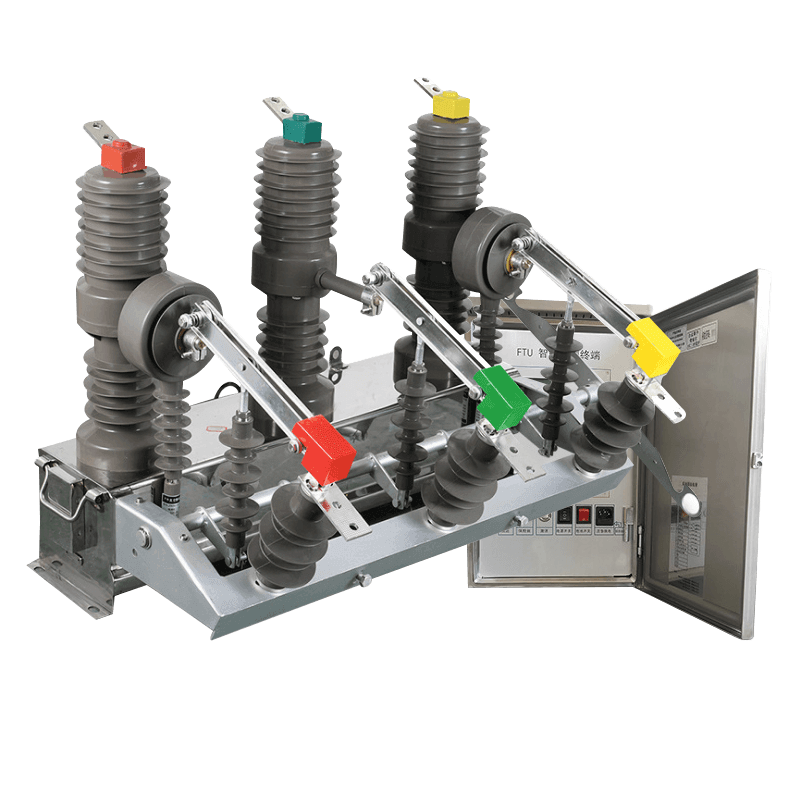

ZW32M (T) - 12 outdoor high-voltage vacuum circuit breaker primary and secondary fusion (with directional judgment)

FLN36-12 indoor high-voltage SF6 load switch

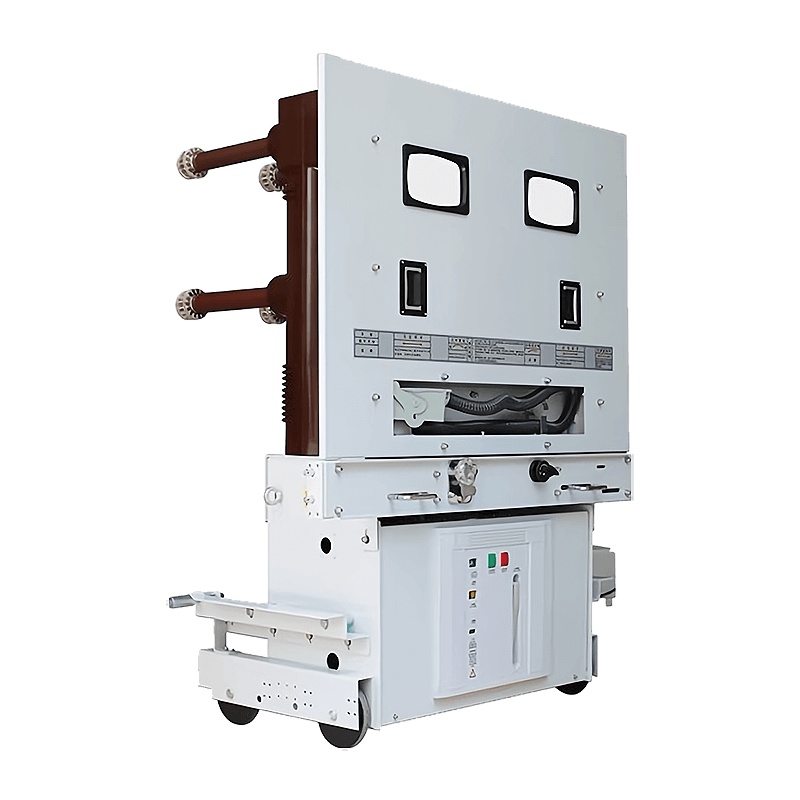

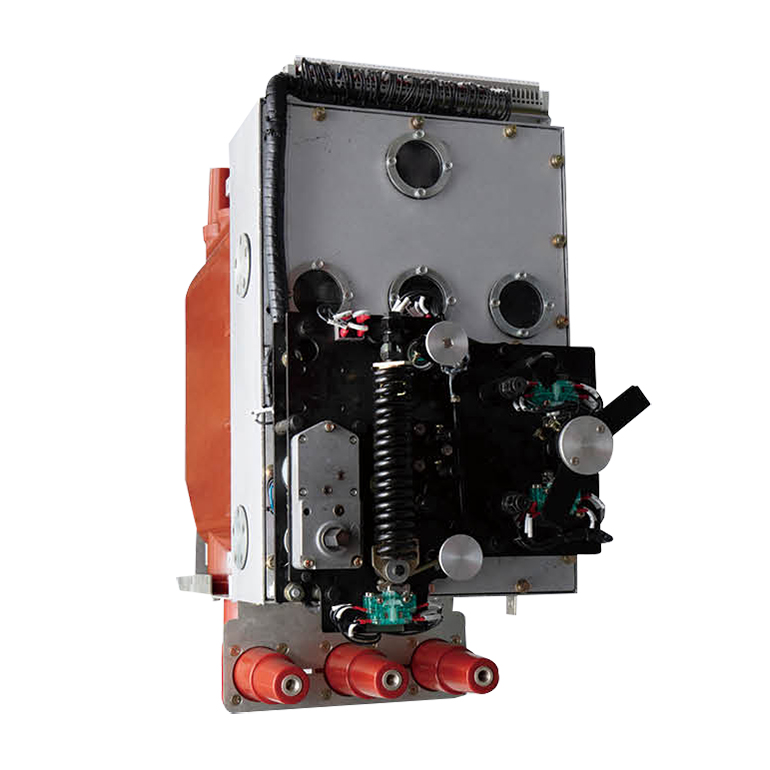

ZN63 (VS1) - 12 indoor high-voltage vacuum circuit breaker/handcart type

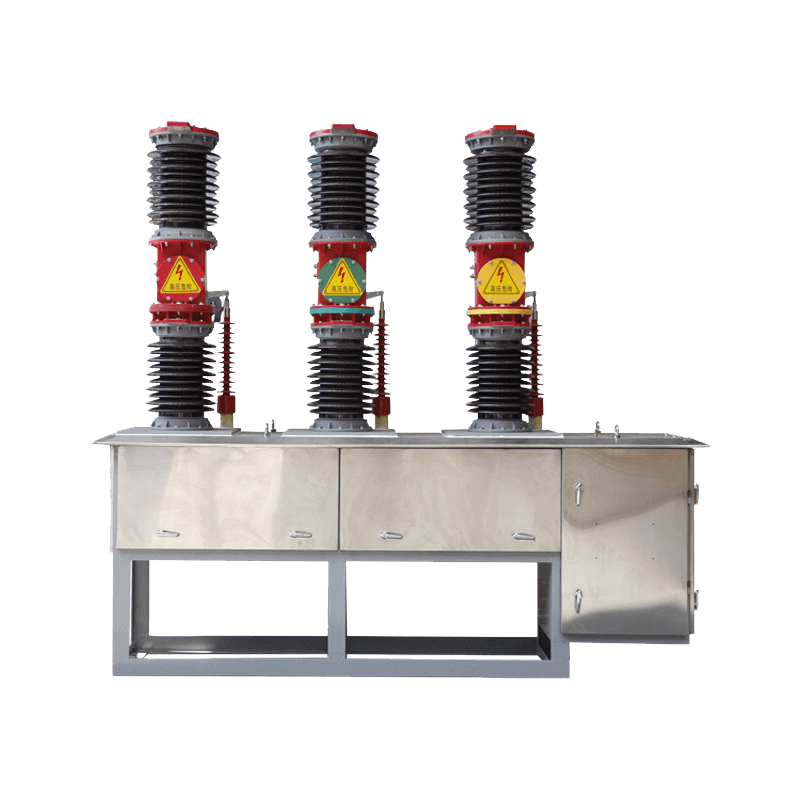

LW8-40.5 Outdoor High Voltage Sulfur Hexafluoride AC Circuit Breaker

ZW32-12 Permanent Magnet Outdoor Vacuum Circuit Breaker

ZN85-40.5 outdoor high-voltage vacuum circuit breaker

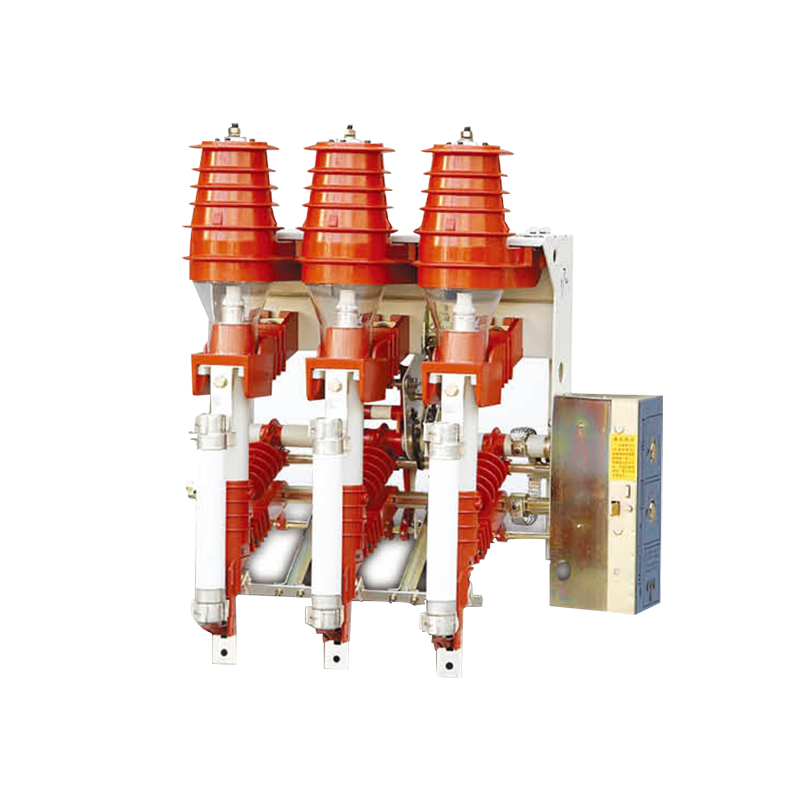

FKN12A-12/FKRN12A-12 Series Compressor Load Switch Fuse Combination

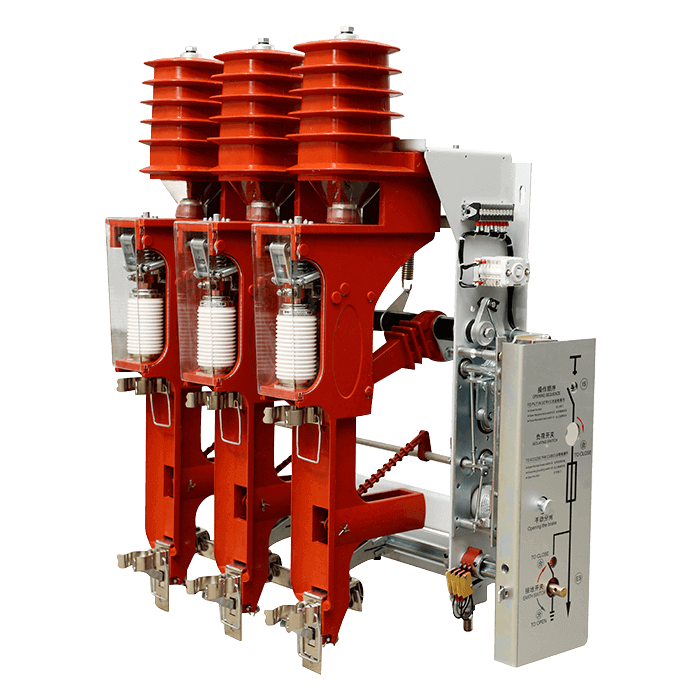

FZN25-12 Series Vacuum Load Switch

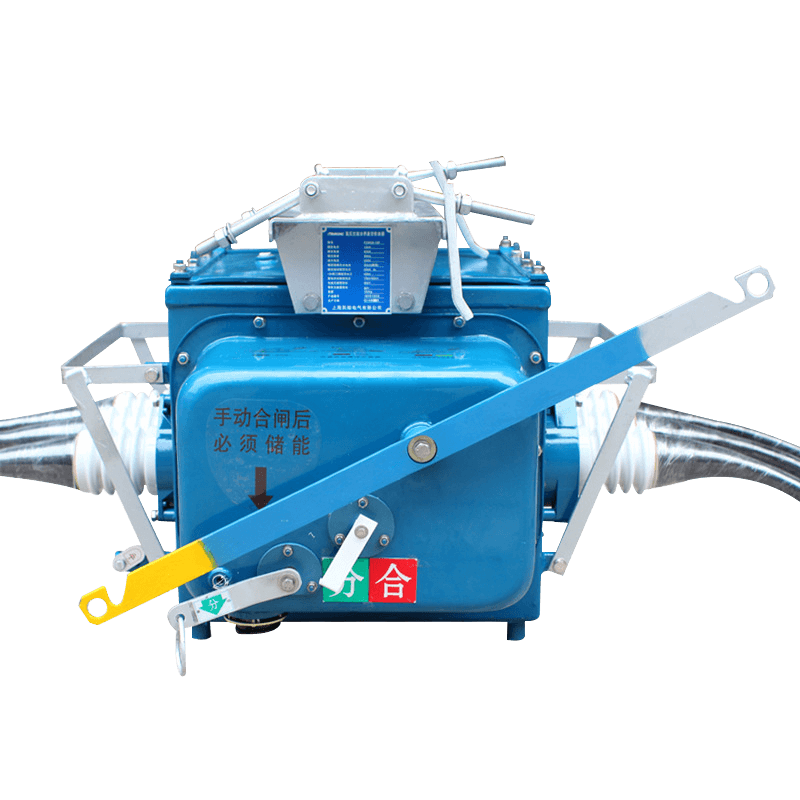

FZW28-12 Series Outdoor Dividing Vacuum Load Switch

ZW8-12/630-20 outdoor high-voltage vacuum circuit breaker

ZW20-12F series outdoor high-voltage AC boundary vacuum circuit breaker

ZW7-40.5 Outdoor Vacuum Circuit Breaker

-

Core components of ring main units

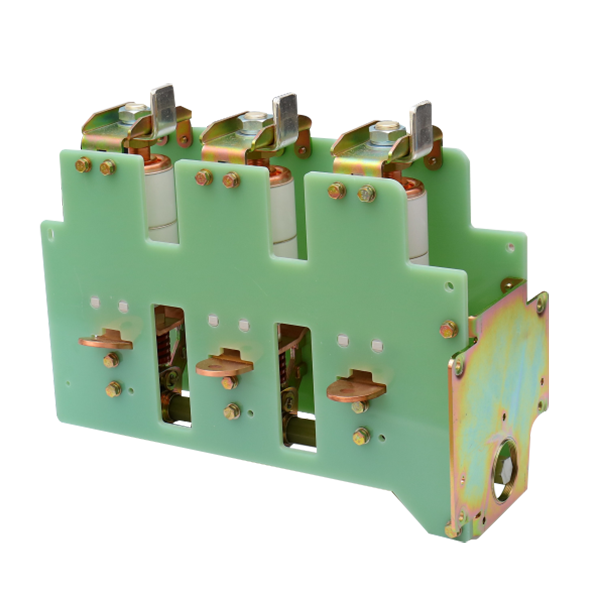

SHV-12/630A gas charging cabinet circuit breaker (with isolation belt grounding)

SHV-12/630A inflatable cabinet router (without isolation and grounding)

SHC-12KV-630A load switch

SHG-12D 630A gas charging cabinet isolating switch

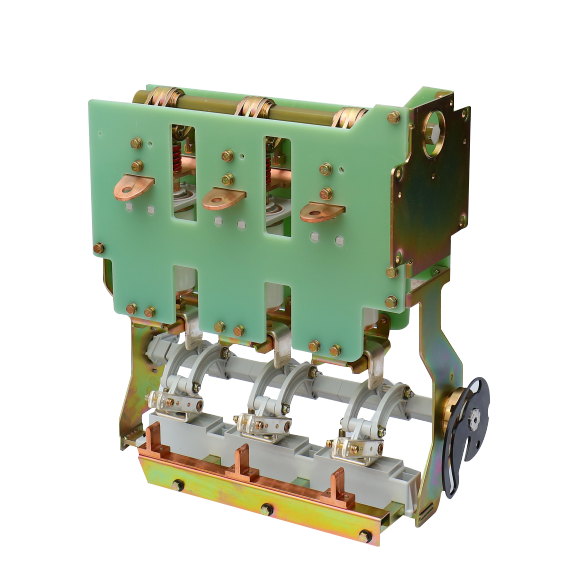

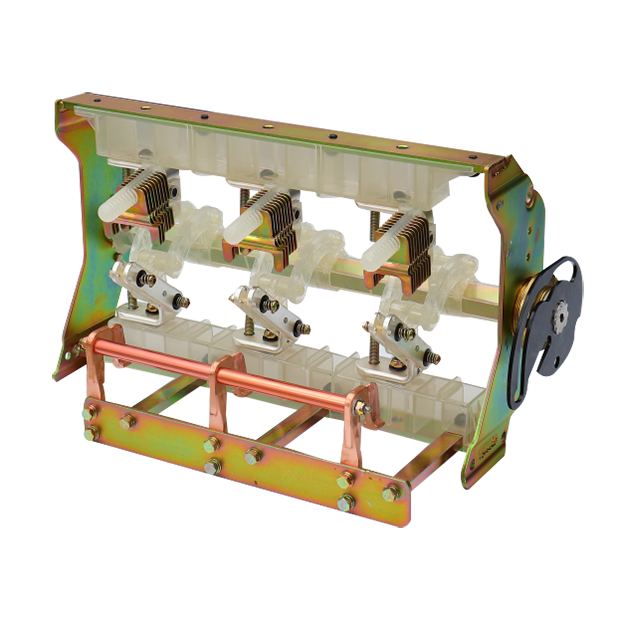

SHSV-12T (D) 630A-25KA solid insulation movement

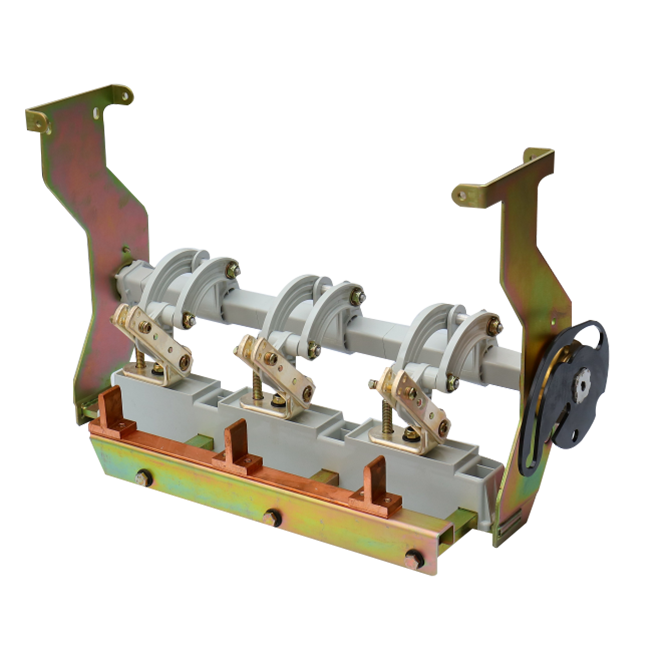

Lower earthing switch

- Application

- News

- Service

- Contact